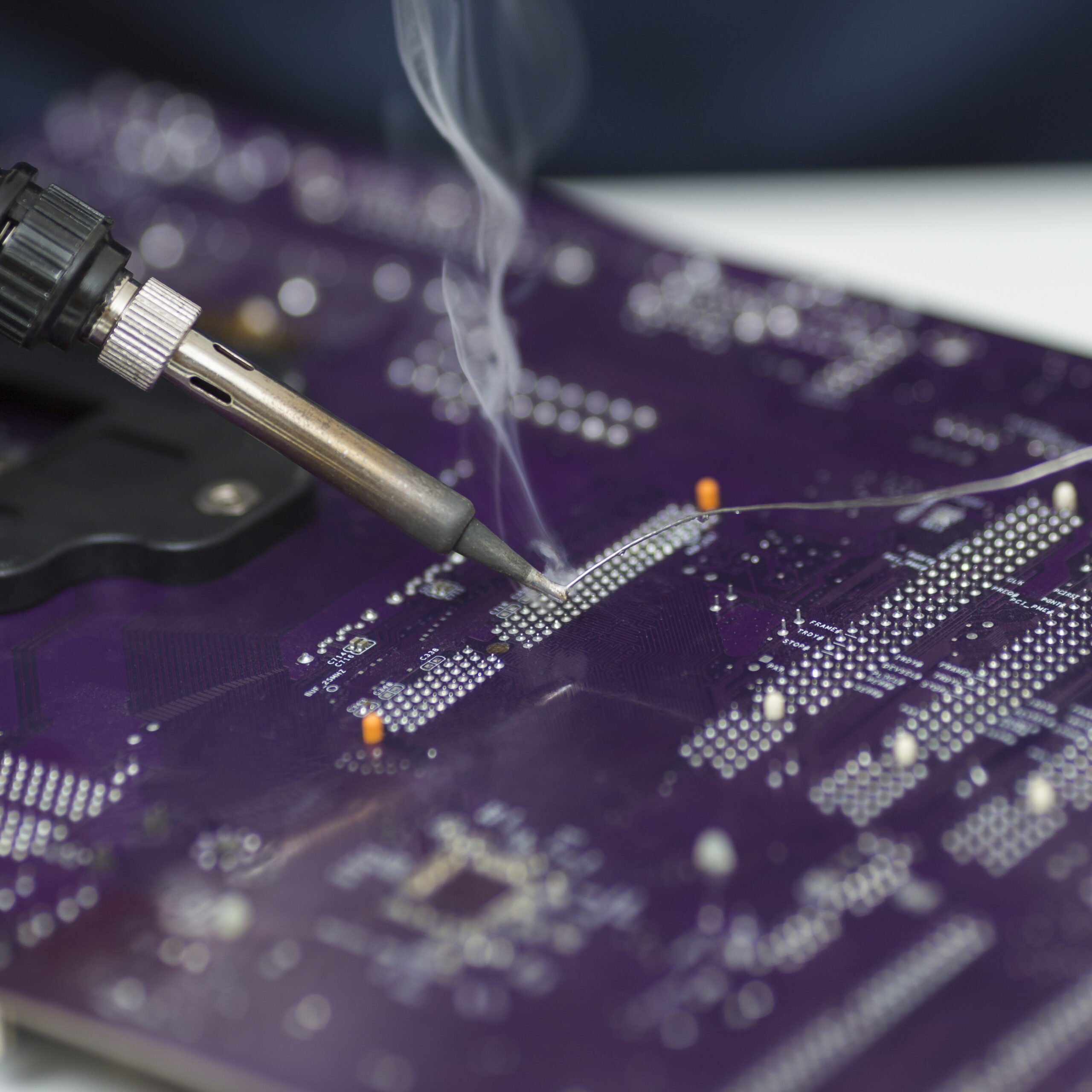

Manufacturing Ability

The company currently operates six SMT production lines, including one Panasonic NPM modular dual-track line (2+1TT2, D3) and five high-end lines composed of YAMAHA models YSM20, YSM10, YS24, and YS12F. All SMT lines are configured with 2+1 and 2+2 setups, featuring two high-speed machines and one multifunctional machine. The SMT workshop has fully matured capabilities in handling 0201 chip components and 0.3mm BGA placement, supported by well-established quality control measures.

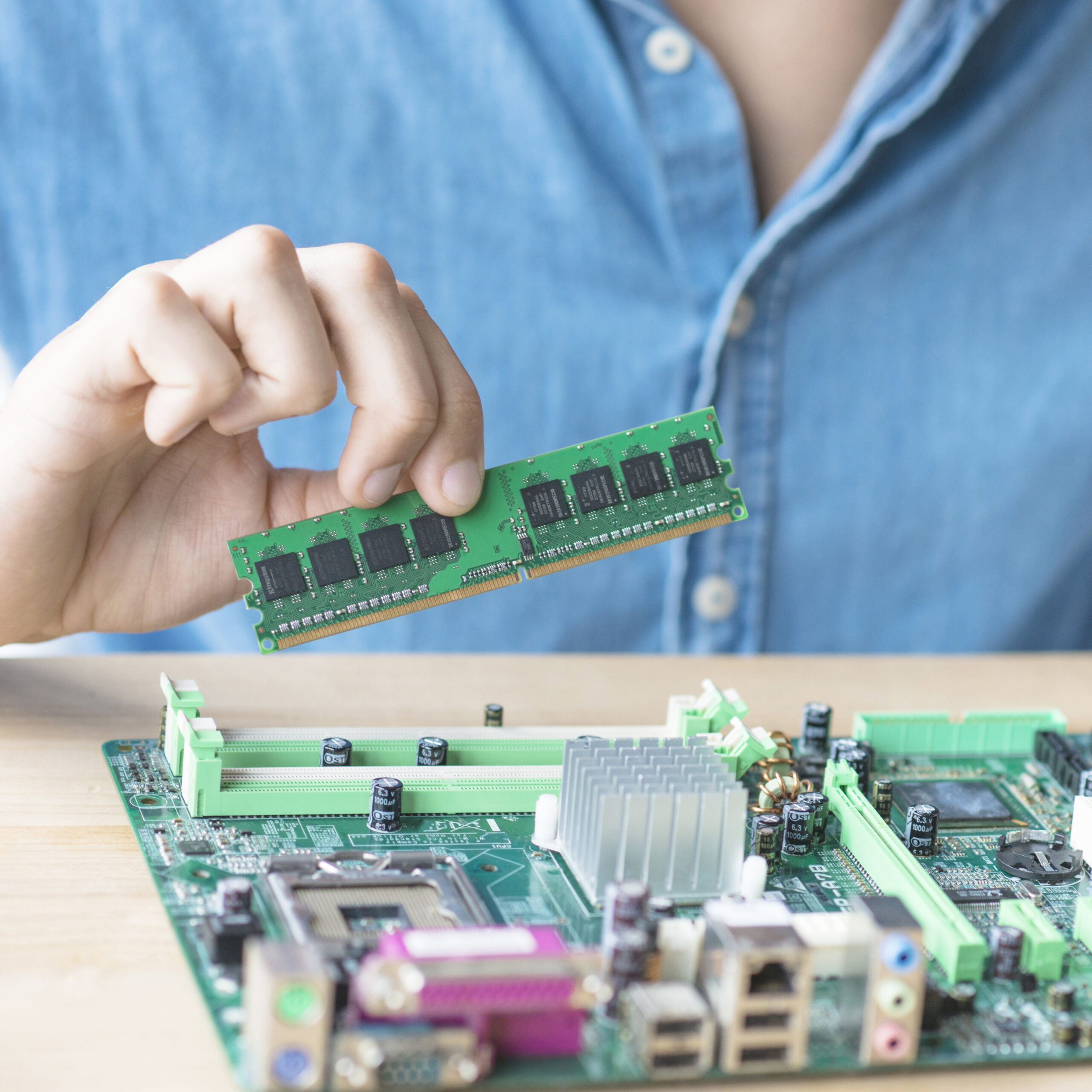

DIP/THT Capabilities

The company operates two advanced wave soldering lines—one for leaded and one for lead-free processes—along with 15 assembly production lines. With an annual production capacity of up to 20 million USB KEY units and 3 million OBU units, we are the largest and most professional USB KEY production base in the northern region. Our comprehensive assembly services cover every step of the process, including software downloading, functional testing, LCD pulse welding, ultrasonic welding, heat staking, final assembly, and packaging.

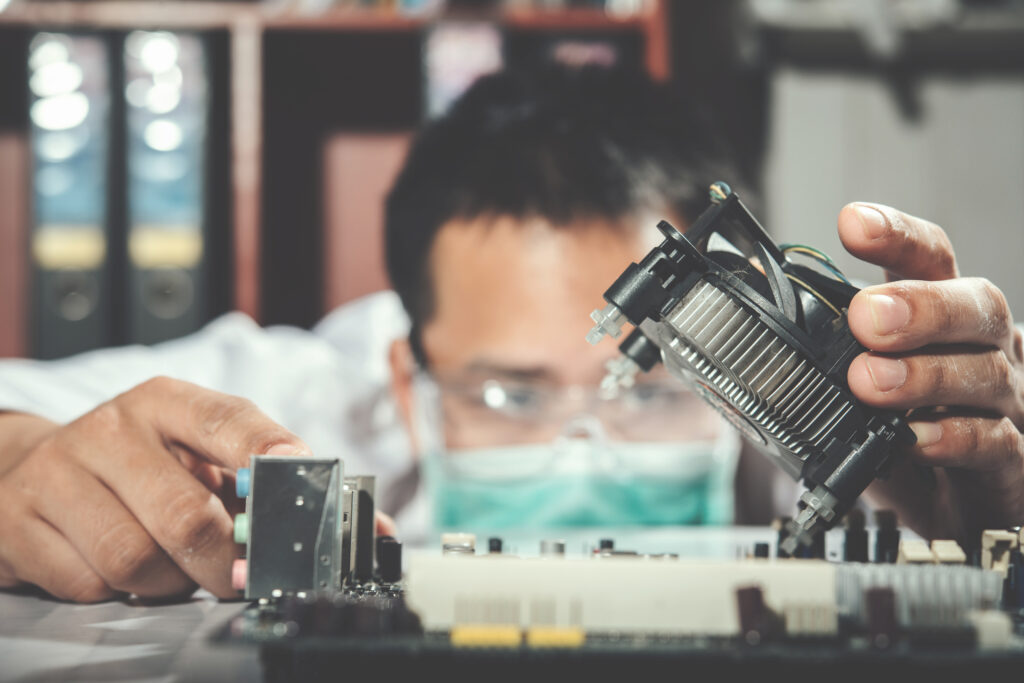

Quality Control

To ensure the highest soldering quality for SMT products, each of our SMT production lines is equipped with fully automated optical inspection (AOI) instruments and 3D Solder Paste Inspection (3D SPI) systems. For BGA soldering quality assurance, we utilize the AX8200 X-RAY inspection system, which offers high capacity, resolution, and magnification. Additionally, to guarantee the quality of fully assembled products, we have invested in a comprehensive range of ICT (In-Circuit Testing), FCT (Functional Circuit Testing), PCBA function testers, and precision measurement instruments. These advanced systems ensure consistent product quality and reliability.